Beyond the Hull: How Hydrodynamics Influence Marine Interior Outfitting

The maritime industry is one of the few sectors where time is the most valuable capital and there is no room for error. Attempting to coordinate numerous different suppliers during a ship’s construction or refurbishment (refit) creates a significant operational risk for shipyards and shipowners. At this point, turnkey marine interior solutions stand out as the most effective strategy that makes complex projects manageable and guarantees success.

As ACCOMAR, we have compiled the technical and commercial advantages of working with a single point of contact in maritime projects, from the design table to the last screw of installation.

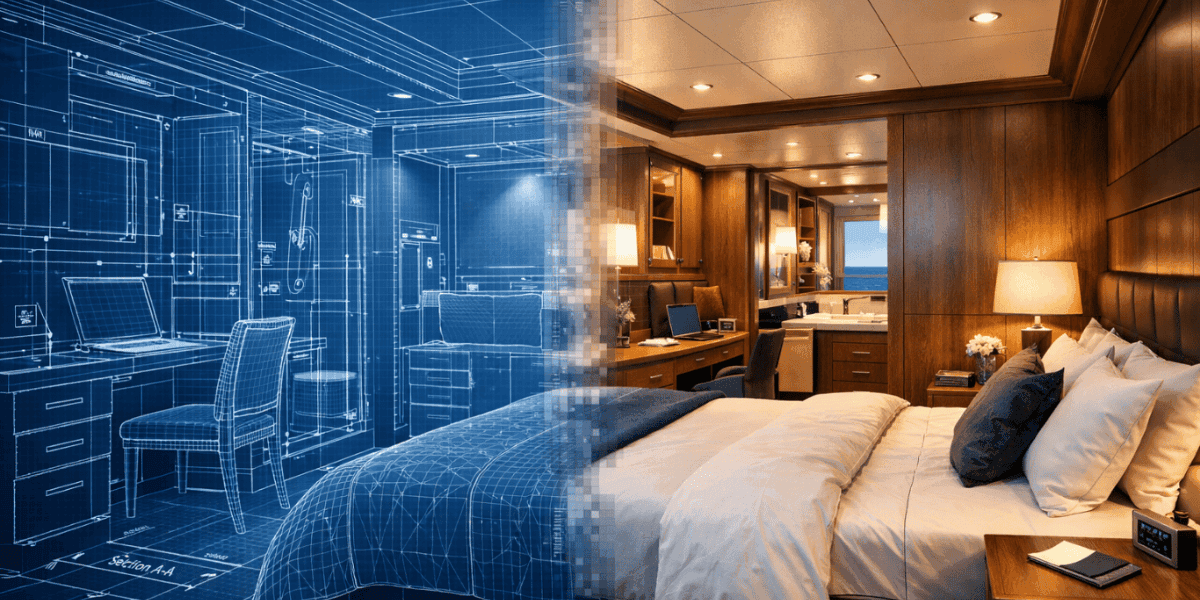

The Importance of an Integrated Design and Implementation Process

In traditional methods, it is common to work with one firm for flooring, another for furniture, and a third for insulation and panels. However, this fragmented structure can lead to communication breakdowns, material incompatibilities, and, most importantly, schedule delays in marine outfitting processes.

Turnkey service means that the entire responsibility of the project is unxdertaken by a single expert partner. At ACCOMAR, this approach covers the following services:

- Interior Architecture & Concept Design: Creating the aesthetic and functional configuration of the space.

- Project Coordination & Master Planning: Synchronizing and managing the entire process with the shipyard schedule.

- Detailed Engineering of Supplied Materials: Technical compatibility and detailed engineering solutions for products.

- Procurement & Supply Chain Management: Ensuring materials arrive on site on time via global logistics networks.

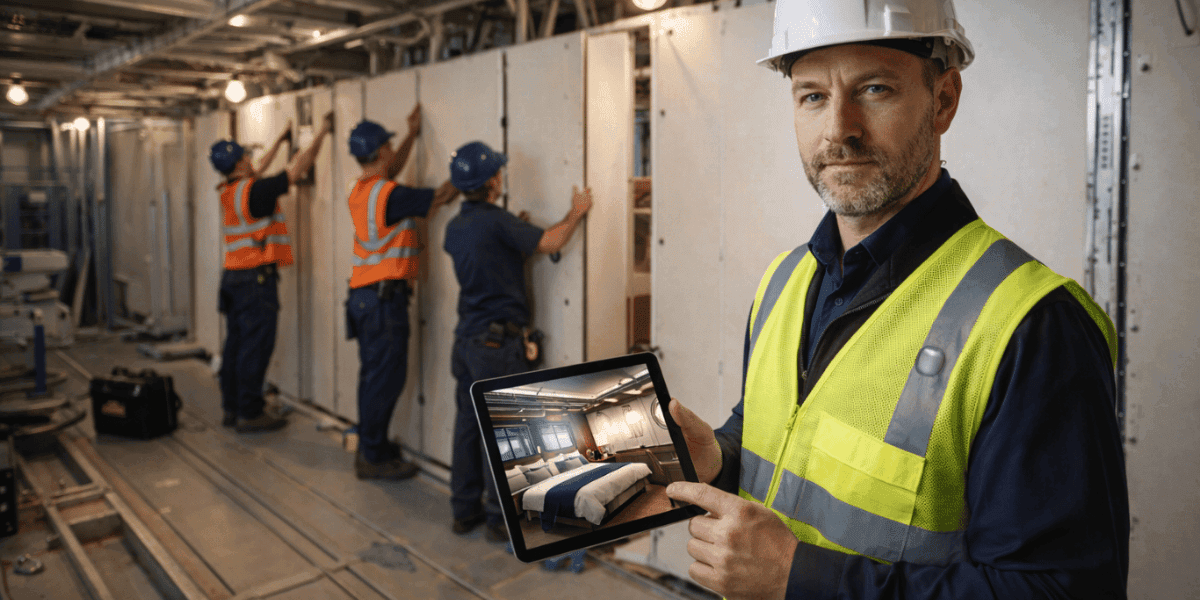

- Workmanship & Onboard Installation: Precise application and installation performed by expert teams.

- High Quality & Long-Term Warranty: Post-delivery confidence and sustainable support.

Key Advantages for Shipyards and Shipowners

- Seamless Project Coordination and Time Savings

In a multi-supplier structure, if one link breaks, it affects the entire chain. However, a single partner specialized in marine interiors solves potential crises before they even arise. ACCOMAR acts as the sole responsible party from the beginning to the end of the project, which relieves the “micro-management” burden on shipyard managers.

- Budget Control and Transparency

Budget deviations are one of the biggest problems in shipbuilding projects. Instead of surprise costs arising from different items, expenses are clarified at the beginning of turnkey projects. The budget allocated for marine outfitting is managed transparently, with efficiency being the main principle.

- Full Compliance with IMO and SOLAS Standards

Safety in maritime is not a choice, but a necessity. Every material, panel, and fabric used must comply with IMO standards (International Maritime Organization) and fire safety regulations. an expert partner is mastered in certification processes and selects materials that will not cause issues during inspections.

The ACCOMAR® Approach: Your Project’s Solution Partner

For us, the process is not just about a drawing on paper. From ferries to offshore platforms, from cruise ships to naval projects, we aim to reflect the design to the field completely.

ACCOMAR’s turnkey marine interior solutions combine aesthetics with engineering. Durability, crew and passenger comfort, and operational ease are among our priorities. With our global logistics network and field experience, regardless of which shipyard in the world your vessel is located in, we deliver your project on time and with the committed quality.