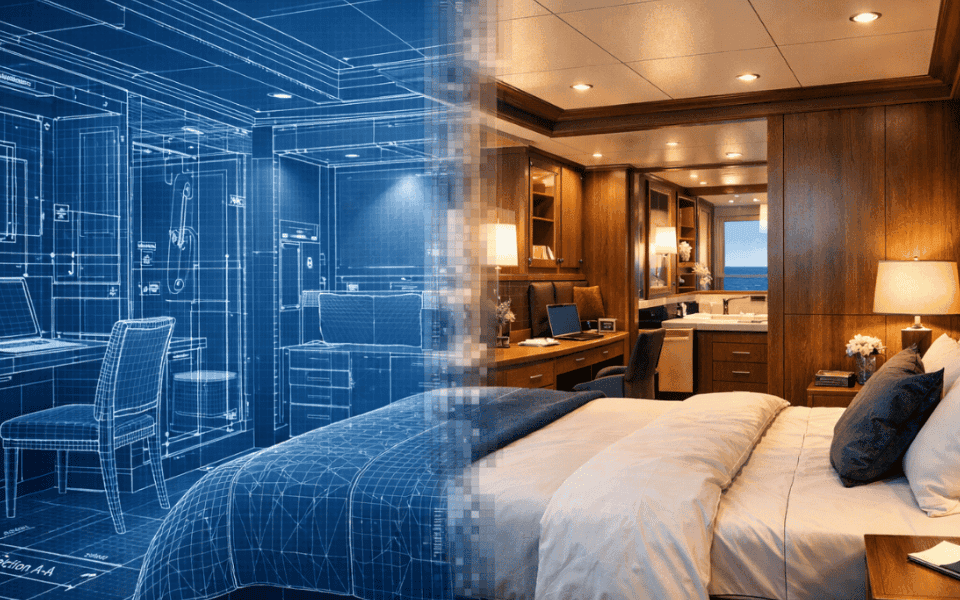

Redefining the Inside Cabin: Modern Interior Design Strategies at Sea

Benefits of Turnkey Interiors in Shipbuilding

A ship must operate within a fluid environment, constantly interacting with waves, currents, and wind. While naval architects focus on hull forms to minimize resistance, for a marine interior outfitting specialist like Accomar, the focus shifts to how these forces are “felt” inside the vessel.

The interaction between a ship and the water doesn’t just dictate fuel efficiency; it directly impacts the safety, comfort, and experience of crew and passengers. Understanding the principles of hydrodynamics is crucial not just for building the steel structure, but for designing resilient, comfortable, and high-quality marine interior solutions.

From Hull Motion to Passenger Comfort

Every floating body exhibits six degrees of freedom: heave, sway, yaw, roll, pitch, and surge. These motions are governed by the hydrodynamic properties of the surrounding flow. However, for a guest on a cruise ship or a crew member on an offshore vessel, these technical terms translate simply to “comfort” or “seasickness.”

In ship interior design, we must account for these dynamic movements:

Securement & Safety: Cruise ship furniture and loose equipment must be designed with “sea-fastening” in mind to prevent movement during heavy rolls or pitches.

Layout Optimization: Understanding where the vessel experiences the most heave (vertical motion) helps in planning high-traffic areas versus cabins, ensuring superior passenger comfort.

Ergonomics: In offshore interior design, where vessels face harsh sea states, cabinetry and workstations are designed to support the crew’s balance and safety during operation.

The Silent Enemy: Hydrodynamic Noise and Vibration

Hydrodynamic forces exerted on the hull structure do more than move the ship—they generate energy that travels through the steel. The flow of water around the hull and the operation of propulsion systems create vibrations and underwater noise.

Without expert marine interior outfitting, this noise transfers directly into cabins and public spaces, ruining the onboard experience. At Accomar, we bridge this gap by implementing:

Vibration Damping Materials: Specialized sub-floors and floating floor systems that decouple the interior from the steel structure.

Acoustic Insulation: High-grade wall panels and ceiling systems designed to absorb structure-borne noise caused by hydrodynamic loads.

By addressing these factors, we ensure that the luxury cruise ship interior design remains a sanctuary of silence, regardless of the conditions outside.

Durability in a Dynamic Environment

Ships are not static buildings; they flex and twist as they move through waves (hogging and sagging). Hydrodynamic loads create stress on the ship’s structure. A rigid interior design in a flexible ship hull is a recipe for failure—cracked panels, misaligned doors, and squeaking joinery.

Professional ship interior outfitting requires materials and installation techniques that allow for this natural movement. Whether it is a newbuild or a refurbishment project, Accomar selects flexible mounting systems and durable materials that withstand these continuous hydrodynamic stresses without compromising aesthetic appeal.

Conclusion: Engineering Meets Aesthetics

While we do not design the hull or the propeller, we deeply understand the environment our interiors must survive in. Hydrodynamics forms the scientific backbone of ship operation, but it is the quality of the marine interior that determines the quality of life on board.

At Accomar, we combine technical understanding with architectural excellence to deliver turnkey accommodation solutions that are as robust as they are beautiful.