Project Coordination for Perfect Ship Interiors

Cruise Cabin Types

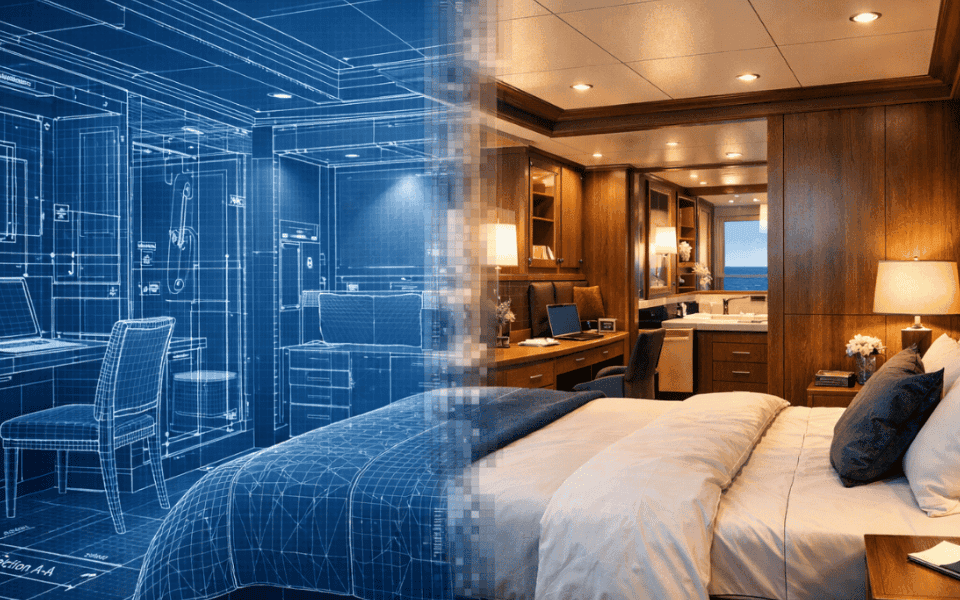

Concept-to-Installation: Accomar’s Turnkey Marine Plywood Workflow

A ship’s interior design process is not just about aesthetic appeal. The safety, functionality, and longevity of the ship’s furnishings are just as important as their design. This is why the marine plywood workflow must be well-managed and meticulously handled from concept to installation. At ACCOMAR, we step in as experts in project coordination and master planning for marine plywood, ensuring that every stage of the process is flawlessly executed.

From Concept to Implementation: The Beginning of the Process

A proper planning process is essential for the successful completion of ship interior design projects. At ACCOMAR (cruise ship manufacturing company), we begin with a meticulous approach from the concept stage. At this stage, we bring all stakeholders together to establish a seamless communication flow. During planning, we:

Analyze the requirements for the ship’s interior design in detail.

Plan and select the materials to be used in interior furnishing applications.

Create a roadmap for both material procurement and logistics to streamline the process.

This comprehensive planning phase ensures smooth collaboration between the designer, planner, contractors, and shipowners, building a strong communication network.

Marine Plywood Workflow: Step-by-Step Process Management

The selection of materials for ship interiors directly impacts the durability, safety, and quality of the project. Using the right materials—such as marine-grade plywood—is essential to meet international standards. At ACCOMAR, we manage this process with precision by providing:

Planning and Project Coordination – Selecting the correct plywood type and thickness.

Supply Chain Management – Ensuring materials are delivered at the right place and time.

Inspection and Quality Control – Regularly checking compliance with international standards throughout production and assembly.

Assembly Process Management – Coordinating with contractors to guarantee on-time, complete work, avoiding costly delays.

Through this structured workflow, ACCOMAR guarantees transparent, flawless, and risk-free marine plywood applications.

Why Choose Accomar’s Turnkey Approach?

A turnkey ship interior management approach ensures there are no gaps or disruptions during the ship interior design process. At ACCOMAR, we go beyond simple material selection. We monitor and coordinate every step of the project—from design to assembly—so that the process progresses seamlessly.

This professional oversight provides shipowners and designers with confidence, knowing a single, reliable partner manages their projects. With ACCOMAR’s turnkey approach, your ship interior design process will be delivered on time, within budget, and at the highest quality standards.

Accomar: Your Reliable Partner for Maritime Projects

ACCOMAR supports you at every stage of your long-term, high-value ship interior projects, from concept to final assembly. By managing the marine plywood workflow and ensuring strict compliance with international standards, we eliminate risks, delays, and unnecessary costs.

Our expertise in ship interior project coordination makes us the ideal partner for creating safe, functional, and durable interiors for cruise ships and yachts.

You deserve flawless project management and cost-effective delivery. By working with ACCOMAR, you can confidently move forward with your project, monitor progress transparently, and ensure success at every step.

👉 Contact ACCOMAR today to secure expert management for your next marine plywood or ship interior design project.

> Marine interior design in London